charpy impact test creep relaxation|charpy impact testing : services Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM webXvideo mulher da bunda grande pelada, se arreganhando para as lentes do fotógrafo sem nenhum pudor. A morena tirou a blusinha e o shortinho socado, deixando amostra os peitinhos durinhos e a buceta raspada. Ela fica de quatro empinando seu bumbum gigante pra câmera, exibindo em close o cuzinho que é bem arrombado. A morena se deita de .

{plog:ftitle_list}

Mahalo Food Park, Nova Petropolis, SBC. 504 likes · 2 talking about this · 925 were here. Um novo conceito de Comer, Beber e se Divertir no ABC!

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact .

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM Izod impact strength was assessed using the Zwick//HIT 5.5P impact testing machine in compliance with the ISO 180 standard at 23 °C, with sample dimensions of 80 mm .Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of metals. It is a standardised high strain-rate test that can measure the amount of .

The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . The impact toughness values of the old and new pipe obtained through Charpy impact test were normal. But an abnormal impact toughness was noticed on the weld which .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .

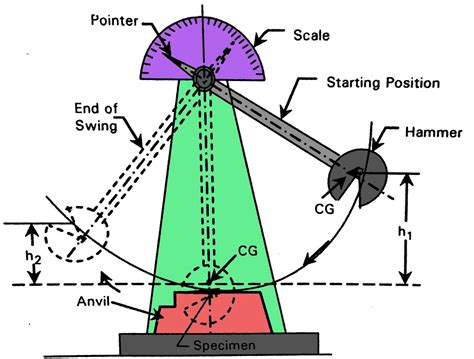

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a). From the three creep settings, elapsed recovery strain values were similar, as were the Charpy impact test data from corresponding VPPMC samples; i.e. there were no significant differences in .

TCR has a comprehensive range of Mechanical Testing services with a dedicated machine shop to assist in sample preparation. Test specimens are duly prepared for metallic and non-metallic materials for the evaluation of tensile, .A widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount . Similarly, the ductility values were lesser in the old pipe and weld when compared to new pipe. The impact toughness values of the old and new pipe obtained through Charpy impact test were normal. But an abnormal impact toughness was noticed on the weld which indicated that the weld had undergone microstructural change when exposed to high .

Published results from creep and stress relaxation experiments based on nylon 6,6 fibre, . Charpy impact testing and debonded area assessment. Charpy impact tests were conducted with a Ceast Resil 25 Charpy machine utilising a 7.5 J hammer at 3.8 m/s, .

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.Chapter 2 – Effects of Processing and Temperature on Charpy Impact Toughness in Metallic Glasses and Metallic Glass Matrix Composites Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM A: The Charpy impact test was developed around 1900 and became known as the Charpy test after its inventor, Georges Charpy. It has since become a standard test method for evaluating material toughness. Q: What types of fractures can the Charpy impact tester evaluate? A: The Charpy impact test can evaluate both ductile and brittle fractures.

charpy testing

What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material’s notch toughness. The objective of the charpy impact test ?? To determine the material resistance to impact from a .The reduced section of a creep test specimen can also be strain-gaged as a means of measuring the amount of strain during testing. . Standard Test Methods for Stress Relaxation Tests for Materials and Structures . At WMT&R Izod and Charpy impact testing are performed on instrumented machines capable of measuring less than 1 ft-lbf to 300 ft .

Creep testing, also known as stress relaxation testing, is performed using specialized fixtures with integral load-sensing electronics. The test specimen is initially loaded to a high stress level and left in that condition to be monitored for either loss of load or deformation under the load. We have several loading fixtures capable of performing creep

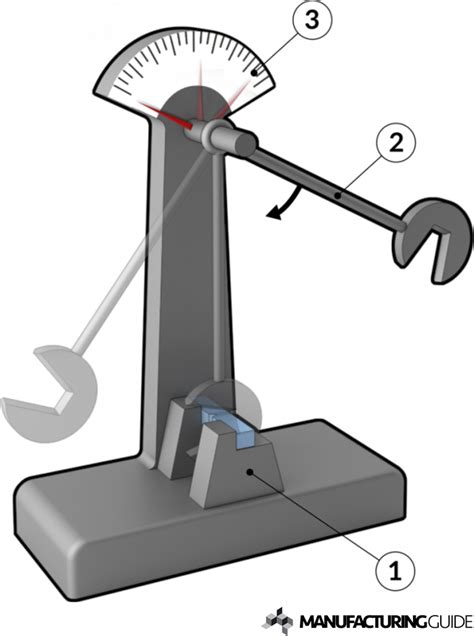

Scope- This standard specifies the Charpy impact ( V-notch ) method for determining impact strength of the metallic material. 2. Principle - This test consists in breaking by one blow from a swinging pendulum, under conditions defined hereafter, a test piece V-notched in the middle and resting on two supports.Part 2: Verification of the testing machine (pendulum impact). (1993). This European standard specifies the impact test according to Charpy (U- and V-notch) for determining the impact strength of metallic materials. For certain special metals and applications the Charpy impact test may be subjected to specific standards or special regulations. 2. The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

Charpy Impact Test. To find the impact resistance of mild steel. Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs. Contact Us Phone: General Information: 011-26582050 Email: [email protected] . Follow Us. AGPL 3.0 .Explanation: In Charpy impact test, the load is applied from backside of the crack, while in Izod test, the load is applied from front side of the crack. . 1 Stress-Rupture Test - 2 Creep Deformation - 1 Creep Deformation - 2 Super Plasticity. Brittle Fracture & Impact Testing. Instrumented Charpy Test Transition Temperature Curve Temper .17.. A charpy impact test measures (a) Tensile strength (b) Ductility (c) Toughness. 18. When a cold worked material is softened by annealing, the processes in softening are (a) creep (b) slip and relaxation (c) recovery and recrystallization. 19. The strain rate increases with time in (a) Primary creep (b) Secondary creep (c) Tertiary creep. 20.

A Charpy impact test measures (a) Tensile strength (b) Ductility (c) Toughness 18. When a cold-worked material is softened by annealing, the processes involved in softening are (a) creep (b) slip and relaxation (c) recovery and recrystallization 19. The strain rate increases with time in (a) Primary creep (b) Secondary creep (c) Tertiary creep 20.Three Stages of Creep Testing . Specimens pass through three different stages during a creep test. The first stage is primary creep, where the creep rate begins by rising quickly and then slows down and decreases. The secondary stage is where the creep rate remains fairly uniform.The Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point of stress concentration within the specimen and improves the reproducibility of the results. The Charpy impact test, just like any impact testing method, determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a .

The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .

charpy impact testing

Vibration Tester commercial

ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.

Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.The great advantage of doing impact testing in-situ in the SEM is that, after impact testing, the sample surface can be directly imaged using high resolution SEM to analyse the residual imprints and learn more about the increase in depth as a function of the number of impacts. Additionally, the combination of the UHSR module with the high temperature module means that the effect .

Single Yarn Strength Tester commercial

Resultado da Grupo. 👤 24.047. Abrir no Telegram. 🔞 Modelos Verificadas. -65.6%. ☝️. Nos ajude a avaliar os links. S. 🔥 vazadinhos privacy BR 🇧🇷🔥 - link do grupo no telegram.

charpy impact test creep relaxation|charpy impact testing